We can custom plastic fabrication parts based on your idea, not only based on for material choosing, but also property requirements custom.

- Shapes, colors, dimensions and propeties can be customized

- Tolerance: +/-0.02mm for plastic, 0.05mm~0.1mm for metal

- Drawing format : CAD / PDF/ DWG/ IGS/ STEP

- Processing: CNC machining, CNC milling and injection,

- Lead Time: 10 ~ 15 days for machining parts, 30 days extrusion & injection mold making and samples

- Packing: carton box, IPPC wooden pallet/plastic pallet - Shipping: by sea, air, TNT/UPS/Fedex/DHL Express

Product parametersPRODUCT PARAMETERS

Why Us

20+ Years Experiences in Plastic Mold Injection Molding Making

-

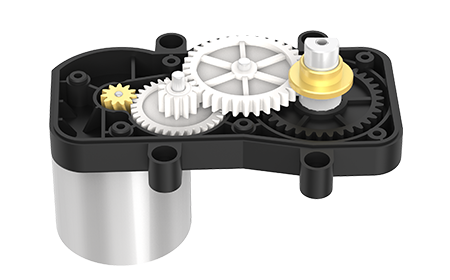

Introduction of Plastic Gear Injection Molding

Forwa Precision was founded in 2002. The production base covers an area of 10,000m². It has 19 years of experience in the production of plastic gear molds. It is a national high-tech enterprise of precision plastic molds and plastic products. , processing, assembly one-stop service, to truly reduce costs and increase efficiency.

The products have passed ISO9001, ISO14001, IATF16949 certification, and strictly implement the standardized quality control system to ensure that each product is qualified to leave the factory. It has provided processing services for many large enterprises such as Nidec, Duya, Axis, Mabuchi, Magna and so on.

-

Request Quote

Request Quote

Processing Power

We Are Relied Upon And Trusted By Our Customers, And We Are Recognized By Them For Our High Quality Products And Attentive Service

-

-

◀ 32 Sets of sophisticated injection molding equipment, the size of the machine is from 30 tons to 380 tons:10 Injection molding machines imported from Japan, including Funac injection molding machines, Nisshin machining centers,

There are 4 injection molding machines imported from Germany, including 4 Arburg injection molding machines.

8 Injection molding machines imported from Taiwan,

10 Haitian precision injection molding machines.

-

-

Excellent plastic product testing equipment: ▶Hexconn imported from the United States is three times a set

Mitutoyo imported from Japan is 3 times a set

One Osaka gear meshing instrument imported from Japan

Two Mitutoyo tool microscopes imported from Japan

One Tesa height gauge imported from the United States

2 Sets of Eason imported from Taiwan

Harbin Jingda Gear Inspection Center 1 set

Mold Display

Comprehensive Manufacturing and Machining Capabilities To Meet All Your Unique Needs

Printer plastic gear

Punch face gear

Punch face gear

Printer plastic gear

Massager gear

Massager gear

Robot sweeper gear

Plastic worm

Plastic worm

Punch face gear

Micro gear motor

Micro gear motor

Show Off

So Far, We Have Completed Nearly 7000+ Projects From Different Industries, Such As Automotive, Consumer Electronics, Smart Home, Security, Medical Andaerospace