Gearboxes are divided into metal gearboxes and plastic gearboxes. Dongguan Kehua Precision Industrial Technology Co., Ltd. has been focusing on the development, design and production of plastic gearboxes for 20 years and enjoys a good reputation in the industry. This is because Kehua Precision has an efficient and united team and advanced processing equipment. So, what kind of equipment is used in the mold processing of plastic gearboxes?

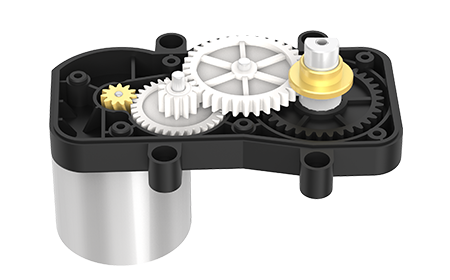

As the saying goes, if a worker wants to do a good job, he must first sharpen his tools. To be able to make a precise gearbox, there must be good equipment. A plastic gearbox is an assembly of multiple parts, such as a plastic casing, a motor tooth, a plastic gear, a planet carrier, a plastic gearbox inner gear ring, and a planetary gearbox base. Most of the mold processing techniques for these plastic parts are similar, and the mold processing equipment used is basically the same.

For example, in the mold processing process of the plastic gearbox shell, there will be rough machining, finishing machining of the mold core, spark machining of the special-shaped part of the mold core, wire cutting processing, and pre-grinding processing and so on. The equipment corresponding to these processes are:

1. The mold core is at right angles, and a grinder is used to process small inserts with regular straight edges, and a grinder is also used.

2. Drill holes and taps on the mold core, and use a milling machine

3. For surface processing, 3D surface processing, electrode processing, machining centers, namely CNC , will be used . Kehua Precision has 8 fully imported machining centers , such as Makino machining centers, Funac carving machines, which are specially used to process copper for copper workers. 3 machines .

4. For some positions to clear the corners, for some blind holes that cannot be processed by CNC , a discharge machine is required. Kehua Precision Industrial Technology Co., Ltd. has 8 discharge machines, namely spark machines , including 3 Sodick spark machines . , 2 Makino spark machines .

5. For some irregular shapes into the sub and through holes, the wire cutting machine is used. Kehua's GF+ Charmilles wire cutting machine is a world famous brand equipment with an accuracy of 0.001mm .

6. Gear hobbing machines, CNC lathes, internal grinders, cylindrical grinders and other equipment are also used in the processing technology of gear molds for plastic gearboxes .

The above list is the main processing equipment for mold processing of plastic gearboxes , as well as some simple and small equipment, which are not listed here. Interested readers can pay attention to the official website of Dongguan Kehua Precision Industrial Technology Co., Ltd.